Dustproof ISO Standard Clean Room with Pharmaceutical GMP Standard

1.Changing rooms and main laboratory have air velocity of over 0.3 m/s. Air shower air velocity should be at least 15 m/s. Air pressure disparity between main clean areas and outside areas should be at least 5 Pa. Interior noise level should not exceed 60 db.

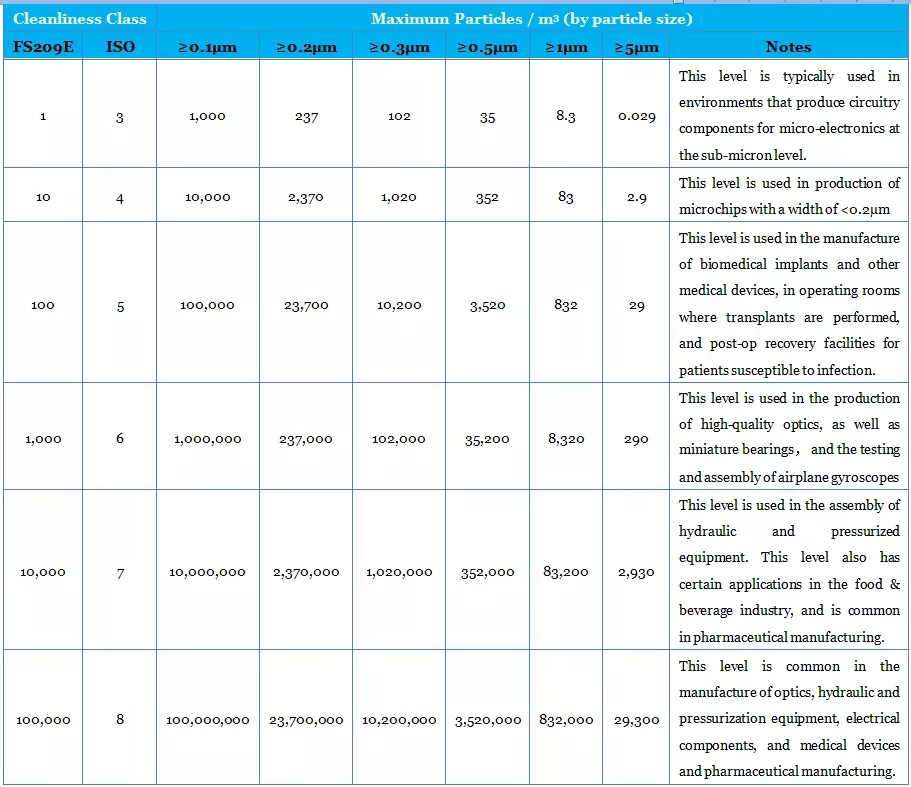

2.Level 2 sterile laboratories are 10,000 Level (ISO 7) in all areas, and 100 Level (ISO 5) in workstations and other critical areas.

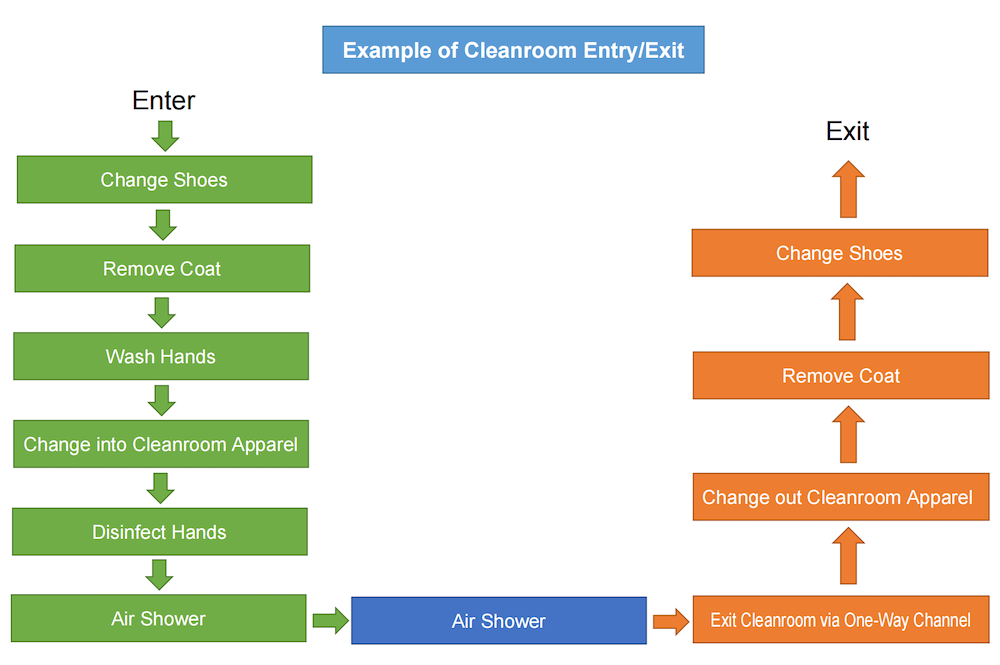

3.The air filtration system for level 2 laboratories includes initial, intermediate, and high-efficiency HEPA filters. These laboratories should employ laminar air flow. Air showers and changing room equipment (sinks, etc.) should all be automatic.

4.Level 3 sterile laboratories are similar to level 2 sterile laboratories in many ways, but they have additional purification equipment to ensure an even more sterile environment. Level 3 laboratories have self-leveling epoxy resin floors, and are equipped with electronic door locks, interlocking pass boxes, and equipment for disinfecting pipes in the laboratory.

5.Most sterile laboratories are negative pressure environments. The lab itself should have a pressure disparity of 30-40 Pa, while the buffer area should have a disparity of 15-20 Pa.

Committed to providing perfect system integration solutions in the fields--Li -battery industry, Pharmaceutical industry, Semiconductor industry, Glass industry (TFT), Solar energy industry, Food industry.

FS209E and ISO 14644 Cleanroom Cleanliness Standards.