Energy-Efficient Industrial Rotary Dehumidifier

Apply to lithium battery,medical equipment,food,pharmaceutical,new energy,and other industries which need dehumidification.Temperature:15-25℃,Relative humidity:5-30%RH,Dew point:-23℃ d p,Wind capacity:300-150000m3/h.

1.Temperature and humidity requirements

2.Length,width and height

3.Air volume,ventilation times,supplu air temperature

4.Clean class

5.The number of staff

6.Whether cold water and steam available

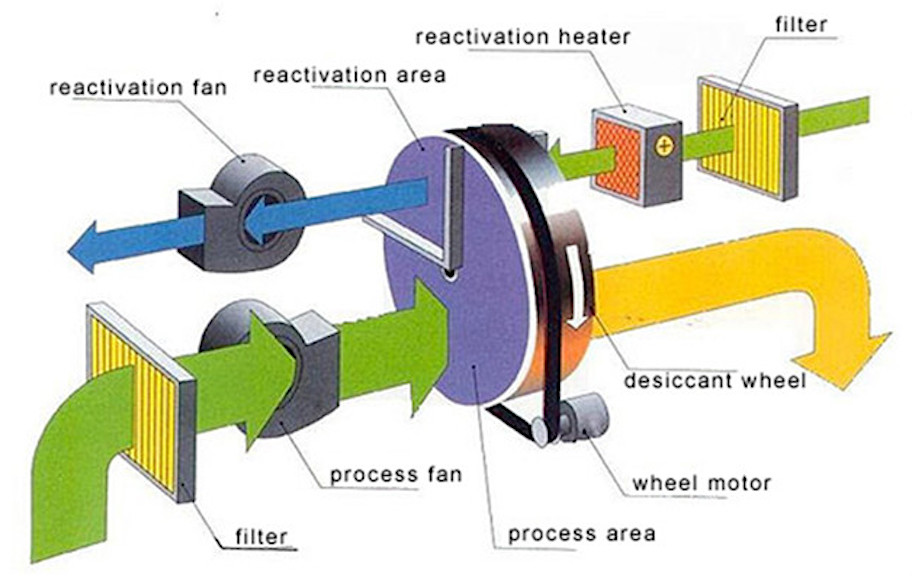

The whole system adopts low wind resistance air treatment structure, low energy consumption technology design and full-automatic control can detect the data at any point of the system and automatically adjust the operation parameters according to the site requirements. At the same time, the most advanced volute free fan can be used to switch between power frequency and frequency conversion, making full use of the special box space of the unit to make the air flow of the whole system balanced, and the operation noise is low Stable operation, low operation cost, high unit efficiency, failure rate ≤ 1%

1.The dew point of the air supply outlet of the low dew point system can reach ≤ - 60 ℃, and the temperature of the control area is 22 ± 3 ℃ and ≤ - 36 ℃

2.The design of regeneration temperature adopts PID analog quantity to adjust regeneration heating temperature to ensure dehumidification effect and save energy consumption

3.Control mode: all data can be displayed on the display screen. It has the function of automatic control of analog quantity adjustment. It can adjust each control node of the operation system according to the temperature and humidity of the workshop site, so that the whole dehumidification system has the advantages of high efficiency, high stability, low energy consumption, simple operation, etc

|

Low Dew Point Wheel Dehumidifier Specification |

|||||||||||

|

Model |

Air Volume (m³/h) |

Dew Point |

Fan (KW) |

Fan (KW) |

Processor Residual Pressure (pa) |

Regenerative Fan Power(KW) |

Processor Residual Pressure (pa) |

Regenerative heating |

Max Power Consumption |

||

|

Electric Heating Power(KW) |

Steam Heating Capacity kg/h |

Electric Heating Power(KW) |

Steam Heating Capacity kg/h |

||||||||

|

JFL-1000DE |

1000 |

-65 |

0.75 |

0.75 |

500 |

0.55 |

200 |

10 |

16.5 |

12.5 |

2 |

|

JFL-2000DE |

2000 |

-65 |

1.1 |

1.1 |

600 |

0.75 |

250 |

18 |

33 |

21 |

3 |

|

JFL-3000DE |

3000 |

-65 |

2.2 |

2.2 |

650 |

1.1 |

300 |

30 |

50 |

35.5 |

4.5 |

|

JFL-5000DE |

5000 |

-65 |

3 |

3 |

650 |

1.5 |

300 |

41 |

67.65 |

48.5 |

67.65 |

|

JFL-6500DE |

6500 |

-65 |

4 |

4 |

600 |

2.2 |

300 |

52 |

85.8 |

62.2 |

85.8 |

|

JFL-8000DE |

8000 |

-65 |

5.5 |

5.5 |

650 |

2.2 |

300 |

59 |

97.35 |

72.2 |

97.35 |

|

JFL-10000DE |

10000 |

-65 |

7.5 |

5.5 |

650 |

3 |

300 |

65 |

107.25 |

81 |

107.25 |

|

JFL-12000DE |

12000 |

-65 |

7.5 |

7.5 |

650 |

3 |

300 |

70 |

115.5 |

88 |

115.5 |

|

JFL-15000DE |

15000 |

-65 |

11 |

7.5 |

650 |

3 |

300 |

85 |

140.25 |

106.5 |

140.25 |

|

JFL-18000DE |

18000 |

-65 |

11 |

11 |

650 |

3 |

300 |

90 |

148.5 |

115 |

148.5 |

|

JFL-20000DE |

20000 |

-65 |

15 |

15 |

650 |

4 |

300 |

96 |

158.4 |

130 |

158.4 |

|

JFL-25000DE |

25000 |

-65 |

18.5 |

18.5 |

650 |

4 |

300 |

108 |

178.2 |

149 |

178.2 |

|

JFL-30000DE |

30000 |

-65 |

22 |

18.5 |

650 |

5.5 |

300 |

127 |

209.55 |

173 |

209.55 |

|

JFL-35000DE |

35000 |

-65 |

22 |

22 |

650 |

6 |

300 |

138 |

227.7 |

188 |

227.7 |

|

JFL-40000DE |

40000 |

-65 |

22 |

22 |

650 |

7 |

300 |

146 |

240.9 |

197 |

240.9 |

|

Note: 1, runner surface wind speed: 2-4m/s for design; Chilled water according to the conventional 7-12℃; 2, the unit size can be installed customer requirements design; 3, regenerative heating method can be based on the customer's heat source (steam, electricity, heat conduction oil); |

|||||||||||